Answer: PU leather is degradable but not biodegradable

Most common PU leather materials are definitely not naturally degradable. With the rapid development of the leather industry, biodegradable plant leather and solvent-free environmentally friendly PU leather have been developed to impact the market. Ordinary PU leather is the most in-demand material in the first-line market and is the most consumed leather fabric. It is used in fashion, sports, furniture, medical, aerospace and other fields. Fashion, sports and furniture have the highest usage and use the most common PU leather. The specific material degradation time is as follows:

| Material | Degradation method | Degradation time |

|---|---|---|

| Ordinary PU leather | Environmental weathering | 200-500 years or more |

| Water-based PU leather | Environmental weathering | 200-500 years |

| Solvent-free PU leather | Environmental weathering | 200-500 years |

| Cactus plant leather | Biodegradation + environmental weathering | 3-12 months and above |

Reasons why ordinary PU leather is not biodegradable

Chemical material synthesis

The reason why ordinary PU leather is non-biodegradable is that its material structure comes from chemically synthesized plastic polymers. It is manufactured through a complex polymerization reaction of polyisocyanates and polyols, two raw materials derived from petrochemicals. During the manufacturing process, a large number of stable and repetitive urethane bonds are produced. These chemical bonds constitute the main chain of the PU polymer, just like using strong rivets to tightly lock thousands of molecular units together, forming a large and tough network or chain structure.

Distinguishing between two degradation modes

Biodegradation:

This method is divided into:

Aerobic degradation: Microorganisms use oxygen through respiration to oxidize organic matter, breaking it down into simpler substances and obtaining energy from them.

Anaerobic degradation: This is a multi-stage process in which different types of anaerobic bacteria work together to gradually break down large organic molecules.

Composting degradation: Moisture, oxygen (through methods such as turning the compost), temperature, and the carbon-nitrogen ratio. Industrial composting can create high temperatures (55-65°C), effectively killing pathogens and weed seeds.

Landfill degradation: After compaction, the oxygen is quickly depleted, and an anaerobic state is established. Organic matter slowly decomposes within the landfill, producing leachate and landfill gas (primarily methane).

Aquatic degradation: In oxygen-rich surface layers of rivers, aerobic degradation is predominant. In oxygen-deficient lakes or ocean sediments, anaerobic degradation is predominant.

Environmental weathering:

Early Stage: Driven by sunlight refraction, oxygen, and temperature fluctuations in the natural environment, PU leather gradually loses its elasticity, becoming dry, hard, faded, and cracked. It’s like a plastic stool exposed to the sun for a long time, crumbling when sat on. Mid-Stage: It becomes brittle due to wind, rain, water flow, and compression. Under sustained physical forces, it tears into smaller and smaller fragments until it becomes rice-sized particles. Late Stage: Continuously subjected to sunlight refraction, oxygen, temperature fluctuations, and compression from wind, rain, and water flow, it transforms into countless particles, and then into microplastics. While seemingly vanishing, they’re actually reduced to tiny particles imperceptible to the naked eye. These nano-microplastics eventually enter the soil, water, air, and are absorbed by plants and animals. Ultimately, they enter the human body through the food chain, posing a long-term health threat to the entire ecosystem and humanity.

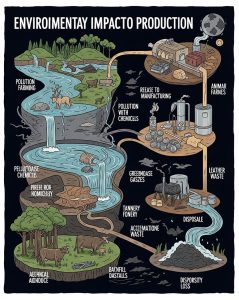

Harm to nature

PU leather doesn’t pose a direct threat to animals, but it’s non-renewable because its raw materials are derived from petroleum and plastics. The production process involves the use and release of volatile organic compounds (VOCs) and other toxic chemicals.

Continuing to release plastic into the environment for centuries will cause ongoing ecological damage. Its only advantage is that it doesn’t directly kill animals, but it can become a chronic source of animal slaughter through ecological damage.

Cactus plant PU biodegradable leather

Plant-based biodegradable leather (cactus, corn, and mushroom mycelium) undergoes a mixed degradation process, but it’s not fully biodegradable. For example, cactus leather degrades by first breaking down the organic components. During the degradation process, enzymes are released to break down these complex organic macromolecules into water, carbon dioxide, and humus, allowing these components to return to nature and contribute to the ecological cycle.

The remaining synthetic components still need to be decomposed through environmental weathering, driven by light, heat, oxygen, and physical forces. Ultimately, these components will become microplastics, remaining in the soil or water and not being recycled naturally.

Objective comparison of PU leather materials

Plant-based biodegradable leather (from cactus, corn, and mushroom mycelium) is a promising alternative. As the most sustainable biodegradable leather, it typically incorporates a PU coating with recycled natural plant materials. This is the fastest way to degrade leather, reducing dependence on fossil fuels and lowering the carbon footprint. Under specific conditions, the material can be degraded by microorganisms, bacteria, and fungi into natural substances such as water, carbon dioxide, and biomass, effectively integrating with nature and avoiding the creation of permanent plastic waste.

Comparison between ordinary PU leather and genuine leather

| Comparison Dimension | Ordinary PU leather | Genuine Leather | Core Differences |

|---|---|---|---|

| raw materials | fossil fuels | Animal skins | Fossil fuels are non-renewable, and animal skins are a natural by-product |

| Production Process | Dependence on petrochemicals, high energy consumption | Animal husbandry itself has a huge carbon footprint; the chrome tanning process produces toxic wastewater containing heavy metal chromium, causing serious pollution. | The main problem with PU is carbon emissions, while the main problem with genuine leather is water pollution and chemical toxicity. |

| Animal Welfare | No harm to animals involved | Directly derived from animals | Vegan vs. Animal Products |

| Durability and lifespan | The lifespan is short (usually 2-5 years) and it is prone to aging, cracking and peeling. | Very durable, with proper care it can last for decades or even longer, developing a unique vintage patina. | Consumables vs. Durable Goods |

| Degradation and disposal | Non-biodegradable températures, weathering into microplastics in the environment over 200-500 years | The tanning process causes it to degrade extremely slowly (about 50 years) and may release heavy metal chromium to pollute the soil. | Plastic pollution vs. heavy metal pollution |

| Cost and Price | Low price, suitable for fast fashion and low-cost products | Expensive, high-end material | Economy vs. Luxury |

| performance | Good waterproofness, uniform appearance and various colors | Good breathability, unique texture, each leather texture is different | Functional stability vs. natural texture |

Comparison between ordinary PU leather and water-based PU leather

| Comparison Dimension | Ordinary PU leather | Water-based leather | Core Differences |

|---|---|---|---|

| raw materials | fossil fuels | Animal skins | Solvent vs. Water |

| Production process | Use toxic organic solvents (such as DMF) by wet or dry coating | Use water as dispersion medium, no toxic solvents | The main problem with PU is carbon emissions, while the main problem with genuine leather is water pollution and chemical toxicity. |

| For employee health | The solvent evaporates to produce toxic gases, which can seriously harm workers' health if exposed for a long time. | Non-toxic and harmless, safe production environment | High Risk vs. Safety |

| Production process<br>Environmental impact | Volatile organic compounds (VOCs) emissions cause air pollution; wastewater treatment is complex | No VOCs emissions, cleaner production process and lower energy consumption | Consumables vs. Durable Goods |

| Product Performance | Mature technology, stable performance, good control of indicators such as feel and wear resistance | The performance of the early technology was slightly inferior, but it has been greatly improved and can reach or even exceed the physical properties of solvent-based PU. | Comparable performance |

| Core chemical essence | polyurethane plastic | polyurethane plastic | Exactly the same |

| Degradation and disposal | Non-biodegradable and eventually form microplastics | Non-biodegradable and eventually form microplastics | The ending is exactly the same, both are plastic pollution |

Material comparison of ordinary PU leather vs. cactus leather

| Comparison Dimension | Ordinary PU leather | Cactus Leather | Core Differences |

|---|---|---|---|

| raw materials | Fossil fuels (petroleum), non-renewable | Renewable biomass (cactus), which consumes very little water during growth and absorbs CO₂ | Fossil-based vs. bio-based |

| Production process<br>Environmental impact | Oil extraction and chemical production have a high carbon footprint | Organically grown, pesticide-free, low energy consumption and no toxic chemicals in the processing | High carbon emissions vs. low carbon or even negative carbon |

| Core chemical essence | Pure polyurethane plastic | Mixture of organic matter and synthetic polymers | Pure plastics vs. biohybrids |

| Degradation and disposal | Non-biodegradable, completely remains and breaks into microplastics | Partially biodegradable. The organic part can be broken down by microorganisms, but the synthetic part will remain | Permanent pollution vs. partial return to nature |

| Degradation time | About 200-500 years ago | Unknown. The organic part lasts for several months to several years, and the synthetic part remains for a long time. The degradation rate is slow. | Extremely slow vs. relatively fast but still not ideal |

| performance | Stable performance, but poor air permeability | Good breathability, soft texture, performance close to real leather | Artificial vs. Natural |

| cost | Lowest cost | The highest cost, belonging to the emerging high-end environmentally friendly materials | Huge cost gap |