What Exactly Is PU Leather?

PU leather is a type of artificial leather, also known as polyurethane leather. It is a substitute for genuine leather. It is made by coating polyurethane resin on a base fabric. The surface can be customized with rich texture effects, imitating the skin of animals and plants. It has real skin feel, wear resistance, waterproof, sweat absorption and other physical properties. It is also called vegan leather and is widely used in grips, balls, bags, shoes, furniture, clothing, packaging and other fields.

How Is PU Leather Made? – The Manufacturing Process

Before producing PU leather, we need to know its production process. Different from PVC leather process, it is divided into dry process and wet process.

Сухой процесс

- Release paper is fed in.

- Colored polyurethane resin is applied to the release paper, dried, and then moved to the next step on the same production line.

- After the release paper is coated with colored polyurethane resin, adhesive is applied to the surface.

- The patterned dry-process polyurethane resin film is produced.

- The patterned polyurethane resin film is then bonded to the base fabric on the same production line.

- The release paper and polyurethane resin are separated, the release paper is recycled, and the laminated dry-process PU semi-finished product is rolled up. The release paper is also rolled up and recycled for reuse when the same pattern is needed.

The above is the production process of PU semi-finished products. After these processes, the PU has not yet produced texture and feel. The following wet process is described.

Влажный процесс

- DMF solvent, other fillers, and additives are added to a polyurethane resin to create a mixture. After vacuum degassing, the mixture is impregnated or coated onto a base fabric. The mixture is then placed in water to displace the solvent (usually DMF). The polyurethane resin gradually solidifies, forming a microporous polyurethane grain layer. This is then rolled, dried, shaped, and cooled to produce semi-finished leather base (BASS). The base is then further dry-processed with veneer or subjected to surface printing, embossing, and refinishing processes to create finished polyurethane synthetic leather. This synthetic leather exhibits excellent moisture and breathability, a soft, full, and light feel, and more closely resembles the style and appearance of natural leather. This step is crucial, distinguishing it from dry-process PU production. To prepare semi-finished base leather, DMF solvent, other fillers, and additives are added to a polyurethane resin to create a mixture. After vacuum degassing, the mixture is then impregnated or coated onto a base fabric. The mixture is then placed in water to displace the solvent (usually DMF). The polyurethane resin gradually solidifies, forming a microporous polyurethane grain layer. This is then rolled, dried, shaped, and cooled. This entire process is completed on the production line shown in the image below.

- The steps for applying the polyurethane resin film to the release paper are essentially the same as for the dry method, except that the base fabric is replaced with a semi-finished leather base with a base fabric attached. The release paper is then peeled off and recycled in the same manner as for the dry method.

- Both the dry and wet methods require a rubbing treatment, which creates the grain and enhances the feel. A single machine can hold approximately 300-400 meters of PU. While rubbing treatment will produce a noticeable grain on standard PU, resulting in a particularly soft feel, this step will inevitably lead to irregular creases on mirror-finished PU.

Types of PU Leather (Regular, Water-based、Solvent-Free, etc.)

Обычная полиуретановая кожа

Ordinary PU leather is one of the most widely used types of leather. It is popular among users for its physical properties such as wear resistance, scratch resistance, waterproof and sweat absorption, and rich texture, but it is not environmentally friendly.

Кожа на водной основе

The biggest advantage of на водной основе PU leather is environmental protection. The production process uses water as the main solvent, instead of using harmful chemicals and solvents like ordinary PU leather. It is harmless to the health of employees during the production process, and also reduces the emission of waste gas and wastewater, playing a role in protecting the environment. This type of product is widely used in the luggage and fashion field.

Полиуретановая кожа без растворителей

Solvent-free PU leather and water-based PU leather are both more environmentally friendly than ordinary PU. The difference between them and water-based PU is that solvent-free PU uses water as a solvent, while water-based PU uses deionized water. Solvent-free PU does not use any low-boiling point organic solvents during the production process, while water-based PU is dispersed in water after the reaction is nearly complete. Its wear-resistant properties are usually used in products such as sofa мебель and car seats.

PU Leather vs. Genuine Leather – Key Differences

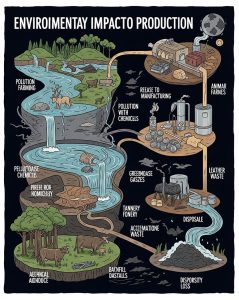

The difference between PU leather and genuine leather is that PU leather is artificially synthesized, while genuine leather comes from animal skin. Although the former does not require hunting animals, it causes certain damage to the environment. The advantage of the latter is that it does not affect the environment and can achieve a short-term biodegradable effect, but it will destroy the ecological balance and cause the extinction of endangered animals. In addition, PU leather is better than genuine leather in wear resistance, waterproofness, and sweat absorption. It is controllable.

PU Leather vs. PVC Leather – Which Is Better?

PU is more environmentally friendly than PVC and has a softer feel. PVC has high wear resistance and simple production process, resulting in lower costs. Generally, users prefer more environmentally friendly and comfortable materials.

Physical Properties of PU Leather (Texture, Flexibility, Durability)

In terms of physical properties, PU leather has good heat resistance, breathability and wear resistance. It can also show excellent thermal stability at a temperature of 100°C. Higher temperatures are not suitable, which will cause the material to gradually decompose and performance to decline. In terms of texture, PU leather can be customized to imitate different textures such as animals, plants, and geometric irregular patterns; its flexibility is also an advantage of PU leather. Its softness and skin-friendliness are better than other leathers in clothing and sofa furniture.

Environmental Impact – Is PU Leather Eco-Friendly?

PU leather is an environmentally friendly material, but it is not biodegradable. Ordinary PU leather takes more than 500 years to degrade through photosynthesis and weathering. Water-based and solvent-free PU mainly use water as a solvent during production, which does not cause harm to workers’ health and reduces pollution such as wastewater and exhaust emissions. Their degradation time is more than 200-500 years; however, after the degradation of the three materials, microplastics will still be produced and combined with the soil, which has an adverse effect on the environment.

Common Applications of PU Leather in Different Industries

PU leather is commonly used in bags, sofa furniture, medical beds, racket grips, balls, clothing, jewelry boxes, and vehicle seats.

Pros of PU Leather (Cost, Design Options, Maintenance)

Compared with PVC, microfiber leather, and silicone leather, the cost of PU leather is higher than PVC but lower than other leathers. It can be one of the best alternatives to other materials. In terms of design, we can customize the texture and brand pattern, and produce a piece of leather for you as a sample test to ensure the durability of the leather material and the portability of subsequent maintenance.

Cons of PU Leather (Longevity, Breathability, Aging)

Ordinary PU leather feels softer than PVC, but it is not wear-resistant when used as a material for bags. Its breathability is slightly poor when used for shoes. It will accelerate aging and discoloration in extreme environments, so it needs regular maintenance, otherwise it will affect the appearance of PU products.

How to Identify PU Leather vs. Real Leather

You can tell the difference between the two by:

- Touch: PU leather is typically harder and feels rough, while genuine leather is softer, fuller, and more elastic.

- Visual inspection: PU leather has a smooth, pore-free surface, while genuine leather has more defined pores and patterns.

- Smell: PU leather has a pungent, plastic smell, while genuine leather has a natural leathery scent.

- Ignition: Tear off a piece of fiber from the back of both PU and genuine leather. Upon ignition, PU leather will emit a pungent, plastic smell, while genuine leather will emit a hairy smell and will not form lumps.

- Water testing: PU leather does not absorb water easily, while genuine leather absorbs water more readily.

All of these methods can help you distinguish between PU and genuine leather, ensuring you avoid being scammed when purchasing materials.

Care and Maintenance Tips for PU Leather Products

Generally, products made of PU leather need to be cleaned regularly once a month with professional cleaning tools to ensure the life of your product. When using PU leather products, avoid exposing them to extreme environments for too long, such as hot summers and extremely cold winters, and humid environments. Exposing them to extreme environments for too long can cause deformation of the leather surface and the growth of mold.

Is PU Leather Waterproof or Scratch-Resistant?

PU leather has the characteristics of wear resistance and scratch resistance, especially the leather represented by solvent-free PU leather. Its biggest feature is wear resistance and scratch resistance. It is usually used in interior decoration of sofa furniture, public transportation, etc. The wear resistance and scratch resistance of traditional ordinary and water-based PU leather are much lower than solvent-free. It depends on the specific scenario you use to ultimately decide what kind of PU leather to use as a reliable material.

Price Comparison – Why PU Leather Is More Affordable

The reason why PU leather is affordable is that it has a large market demand and the material is made of polymer resin and plastic additives, the procurement cost of these materials is much lower than that of genuine leather.

The Future of PU Leather – Trends in Sustainable Materia ls PU

PU leather is an indispensable material in most application fields. Its iteration is getting faster and faster. People need to slowly change their product thinking from ordinary PU to environmentally friendly water-based PU and solvent-free PU leather, and try to protect the concept of environment. At present, many big brand manufacturers are changing the materials of some products to water-based PU and solvent-free PU leather.