microfibra de cuero para zapatos

La piel de microfibra se utiliza para zapatos: zapatos formales, zapatos informales, zapatos deportivos, sandalias, botas, zapatos de tacón, etc. Se utiliza mucho por su buena resistencia al desgaste, transpirabilidad y comodidad. Consulte nuestra serie de productos de microfibra para calzado

Lo mejor para la textura de los zapatos de cuero de microfibra

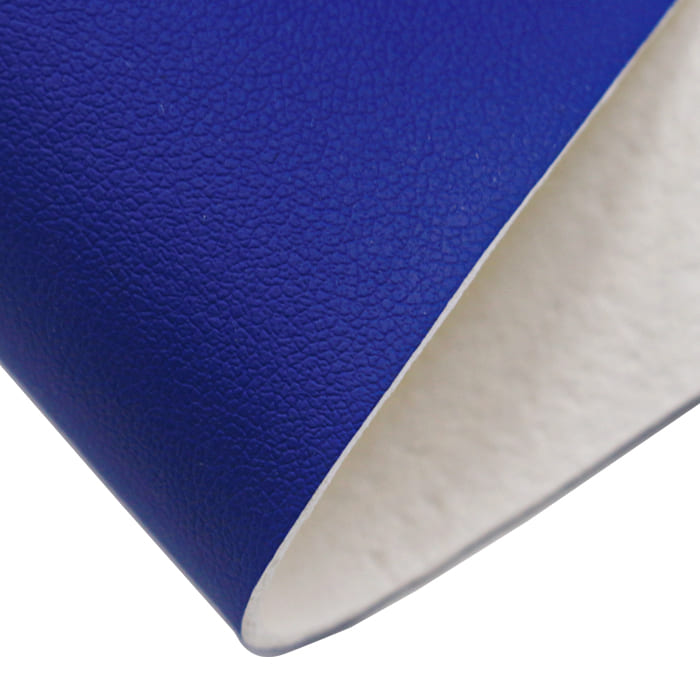

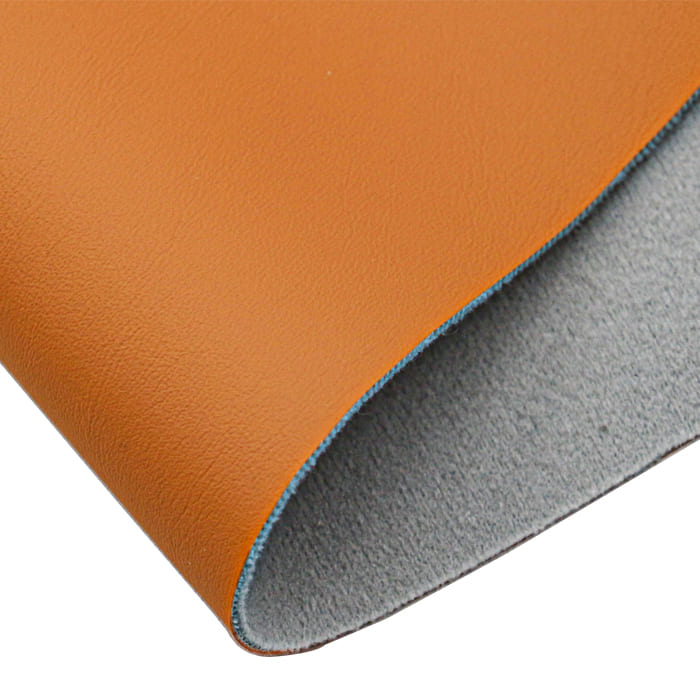

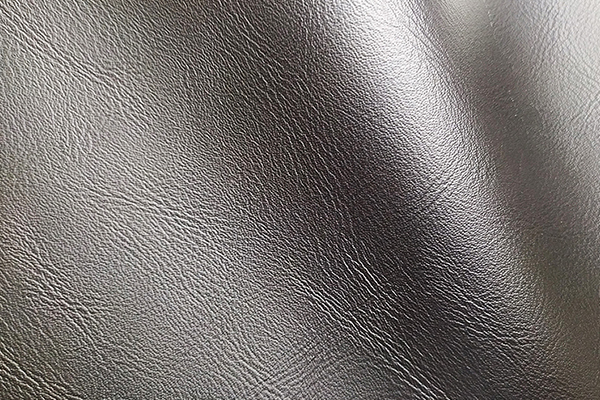

Las texturas de tejido de cuero de microfibra más populares para la fabricación de zapatos, por lo general los zapatos deportivos utilizan lichi, napa, plano, piel de oveja y otras texturas, mientras que los zapatos formales utilizan lagarto, cocodrilo, piel de vaca y otras texturas. Aquí no hay distinción entre zapatos masculinos y femeninos. Por supuesto, hay más texturas entre las que elegir para fabricar zapatos. Consúltenos para saber más sobre texturas

Piel microfibra Color

Características de los zapatos

Resistente al desgaste

El calzado de cuero tiene unos requisitos estrictos de resistencia al desgaste. Según las normas internacionales de ensayo ISO 4649 y ASTM D5963, el índice de desgaste debe ser lo más pequeño posible e inferior a 0,1 milímetros cúbicos por Newton metro (mm³/N-m). Cuanto menor sea este valor, mejor será la resistencia al desgaste del material.

Antienvejecimiento

Los zapatos de cuero suelen tener propiedades antienvejecimiento. Durante la producción de cuero, añadimos disolventes y tratamientos técnicos para que sea más eficaz, y no envejecerá hasta 5 años

No tóxico

La piel de microfibra para calzado utiliza materias primas no tóxicas y cumple las normas medioambientales internacionales. Cada lote de mercancías que producimos será probado por una agencia de pruebas profesional para emitir un informe de prueba para garantizar la seguridad del producto, no se liberan gases nocivos, y crear una experiencia cómoda

Microfibra ecológica

Utilizamos procesos de producción respetuosos con el medio ambiente durante el proceso de producción, controlamos estrictamente el flujo de contaminantes a la naturaleza y causamos daños incontrolables a la naturaleza y a los seres humanos; reducimos significativamente las aguas residuales y las emisiones de gases residuales, reducimos la huella de carbono y hacemos un buen trabajo en el tratamiento de residuos sólidos; el cuero de microfibra para calzado también se deprime y se mantiene para prolongar su vida útil y reducir el consumo de recursos.

Parámetros característicos del producto

| Propiedades químicas (medioambientales) | Propiedades físicas | ||

|---|---|---|---|

| Artículo | Datos/parámetros del proyecto | Artículo | Datos/parámetros del proyecto |

| Microfibra | Microfibra | ||

| Anchura | 52-54" | Porcentaje de elongación (rotura) | R:70% W:200% |

| Espesor | 0,5-1,4 mm | Fuerza de exfoliación | R:8kg W:7kg |

| Plomo | <30PPM | Resistencia al desgarro | R:5kg W:5kg |

| Formaldehído | ≤20PPM K | Resistencia a la flexión | Temperatura ambiente: 70000 veces |

| Feno丨Benceno | <3PPM K | Solidez del color al roce | Limpieza en húmedo:5 niveles Limpieza en seco:5 Nivel |

| Cromo hexavalente | ND | Resistencia a la abrasión | Muela abrasiva H-18 de 500 g de peso, 7000 revoluciones sin daños |

| Colorantes cancerígenos | ND | Resistencia a la hidrólisis | 5-10 años |

| HAP | <2PPM | Solidez del color al amarilleamiento fenólico | Nivel 4 |

| Valor PH | 4-7.5 | ||

| DMFA | ND | ||

| APEO=NPEO+OPEO | ND | ||

| Ftalatos | ND | ||

| Colorantes AZO | ND | ||

| Colorantes dispersos | NONE | ||

| EN71-3 | Cumplir las normas internacionales | ||

| Cloro-sano | ND | ||

| Compuesto organoestánnico | ND | ||

Canales de cooperación

Obtener muestra gratuita

Permanecemos en línea las 24 horas del día a la espera de sus consultas, ya sea para enviarle un correo electrónico, o para llamarle la primera vez que recibamos información y ponernos en contacto con usted para hablar del pedido.

- IDM:Susan Zhang

- Teléfono/Whatsapp: +8613559762001

- Correo electrónico: susanzhang@hw-leather.com

- Skype: susanzhang@hw-leather.com