Ever wondered what happens to that old leather jacket you donated or the offcuts from a factory making luxury handbags? Well, they don’t just disappear into thin air! Thanks to the wonders of recycled leather, what was once destined for the landfill is now being transformed into stylish, durable materials fit for your next must-have accessory. Think of it as the ultimate makeover—where leather scraps go from “trash heap chic” to eco-friendly luxury in just a few steps!

Transformer les déchets en merveilles : Le processus de fabrication du cuir recyclé

Le processus de fabrication du cuir recyclé commence par la collecte de déchets de cuir provenant de chutes industrielles, de produits en cuir de post-consommation ou de déchets issus de la fabrication du cuir. Ces matières premières sont triées, nettoyées et déchiquetées en petites fibres. Une fois déchiquetées, les fibres sont mélangées à des agents de liaison naturels ou synthétiques pour créer un matériau composite. Ce mélange est ensuite pressé et traité pour former des feuilles de cuir recyclé qui reproduisent fidèlement la texture et la durabilité du cuir neuf.

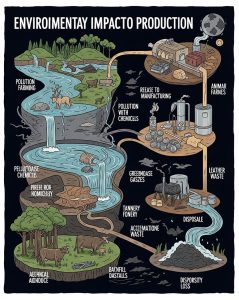

Contrairement à la production traditionnelle de cuir, qui nécessite de grandes quantités d'eau et de produits chimiques pour le tannage, la fabrication de cuir recyclé utilise beaucoup moins de ressources. Il s'agit donc d'une alternative respectueuse de l'environnement qui permet de créer des produits de haute qualité sans contribuer à la déforestation ou à la pollution.

Innovation écologique : Un guide étape par étape pour créer du cuir recyclé

- Collecte : La première étape de la fabrication du cuir recyclé consiste à rassembler les déchets. Ceux-ci peuvent provenir d'articles en cuir de post-consommation, de chutes inutilisées provenant d'usines ou de pièces de rebut provenant de vieux meubles ou d'intérieurs de voitures.

- Nettoyage et déchiquetage : Le cuir collecté est nettoyé pour éliminer toute saleté, huile ou contaminant. Après le nettoyage, le cuir est déchiqueté en petites fibres. Cette étape est cruciale pour transformer le cuir en une forme exploitable.

- Mélange avec des agents de liaison : Les fibres déchiquetées sont ensuite combinées à un agent liant - naturel (comme le latex) ou synthétique (comme le polyuréthane) - pour créer un matériau solide et cohésif. Ce mélange est étalé en une couche uniforme et compressé pour former des feuilles.

- Pressage et finition : les feuilles de cuir recyclé sont pressées sous haute pression pour garantir une bonne adhérence des fibres et des agents de liaison. Une fois pressées, les feuilles sont traitées avec des agents de finition pour améliorer leur texture, leur couleur et leur durabilité, imitant ainsi l'aspect et le toucher du cuir véritable.

- Découpe et assemblage : Une fois les feuilles de cuir recyclé terminées, elles sont découpées dans les formes souhaitées et cousues ou assemblées dans divers produits, des sacs à main aux chaussures en passant par les meubles et les intérieurs de voiture. Le résultat final est un produit qui ressemble au cuir traditionnel, mais dont l'impact sur l'environnement est considérablement réduit.

Upcycling Leather Scraps : Comment fabriquer des matériaux en cuir durables

Le recyclage des chutes de cuir est un moyen créatif et respectueux de l'environnement de donner une nouvelle vie à des matériaux autrement mis au rebut. En réutilisant les restes de cuir provenant de vieux articles ou de processus industriels, le recyclage permet de minimiser les déchets et de réduire la demande de production de cuir neuf. La première étape de l'upcycling consiste à sélectionner des chutes de cuir viables et encore en bon état. Ces chutes sont nettoyées, découpées en formes utilisables et souvent superposées ou rapiécées pour créer un nouveau matériau.

Pour les petits articles tels que les portefeuilles ou les étuis de téléphone, le cuir recyclé peut être coupé et cousu directement sans autre traitement. Pour les articles plus grands, comme les sacs à main ou les vestes, il peut être nécessaire de coller ou de renforcer le cuir avant de l'assembler. L'upcycling est une approche artisanale de la conception durable, où chaque pièce raconte l'histoire d'une transformation - du déchet à l'émerveillement.

L'art de récupérer le cuir : Transformer les déchets en matériaux élégants

Le processus de création de cuir recyclé commence par la collecte de déchets de cuir provenant de diverses sources, notamment d'articles de maroquinerie mis au rebut, de chutes de processus de fabrication et de produits de post-consommation. Ces déchets, qui finiraient autrement dans les décharges, sont nettoyés, triés et préparés en vue de leur réutilisation. C'est l'art de la récupération : prendre ce qui est considéré comme un déchet et lui donner une seconde vie grâce à l'innovation.

Une fois les déchets collectés, ils sont déchiquetés en petits morceaux, puis transformés en une substance semblable à de la pâte. Cette pulpe est combinée à d'autres matériaux durables, tels que des fibres naturelles ou des liants synthétiques, pour créer un nouveau matériau semblable au cuir. Le produit final conserve l'aspect et le toucher du cuir traditionnel, mais avec une empreinte environnementale considérablement réduite. Il s'agit d'un équilibre délicat entre l'artisanat et la durabilité, et le résultat est à la fois fonctionnel et à la mode.

Le recyclage au service de la mode : Comment le cuir recyclé est fabriqué à partir de déchets mis au rebut

Le processus de transformation des déchets de cuir en matériaux utilisables pour la mode comporte quelques étapes clés. Après avoir été déchiquetés et transformés en pâte, les déchets sont pressés ensemble à l'aide de chaleur et de pression pour former des feuilles de cuir recyclé. Au cours de ce processus, les fabricants peuvent ajouter des revêtements supplémentaires pour améliorer la durabilité et la texture du matériau. Ces revêtements peuvent varier, certains utilisant des solutions naturelles à base de plantes pour garantir que le produit reste respectueux de l'environnement.

Une fois les feuilles de cuir recyclé formées, elles peuvent être traitées ou teintées pour répondre à divers besoins en matière de design. La polyvalence du cuir recyclé en fait un matériau adapté à la création de tout, des sacs aux chaussures en passant par le mobilier et les intérieurs automobiles. Le produit final est un matériau durable et souple qui possède les qualités esthétiques du cuir, mais qui est beaucoup plus durable. Les marques de mode adoptent de plus en plus ce processus pour répondre à la demande croissante de produits respectueux de l'environnement.

Des déchets à la durabilité : Dans l'univers de la production de cuir recyclé

Le monde de la production de cuir recyclé est ancré dans le développement durable et vise à réduire l'impact environnemental de la fabrication du cuir. La production traditionnelle de cuir fait souvent appel à des produits chimiques nocifs et contribue à la déforestation due à l'élevage du bétail. Le cuir recyclé offre une alternative, en détournant les déchets des décharges et en réduisant le besoin de nouvelles ressources.

Les installations de production dédiées au cuir recyclé privilégient souvent les pratiques écologiques, telles que l'utilisation d'adhésifs à base d'eau et la réduction au minimum de l'utilisation de produits chimiques nocifs dans le processus de traitement. Cette démarche est non seulement bénéfique pour l'environnement, mais elle garantit également que le produit final est sans danger pour les consommateurs. En outre, en récupérant les chutes de cuir, les fabricants peuvent réduire de manière significative la quantité de déchets générés par les industries de la mode et de la fabrication.

Conclusion :

Le chemin parcouru depuis les déchets de cuir jusqu'à un produit élégant et durable témoigne du pouvoir de l'innovation et d'une conception respectueuse de l'environnement. En récupérant les déchets et en les transformant en produits de remplacement du cuir de haute qualité, le cuir recyclé remodèle les industries de la mode et de la fabrication. Ce processus permet non seulement de réduire la charge environnementale de la production traditionnelle de cuir, mais aussi de donner aux consommateurs la possibilité de choisir des produits à la fois beaux et responsables.

Alors que la demande de matériaux écologiques ne cesse de croître, le cuir recyclé prouve que le développement durable n'implique aucun compromis en termes de style ou de fonctionnalité. Des sacs à main recyclés aux intérieurs de voiture, ce matériau est à l'origine d'une révolution dans le domaine de la mode circulaire et de la fabrication écologique. La prochaine fois que vous choisirez du cuir recyclé, n'oubliez pas que vous ne faites pas qu'acheter, vous faites une déclaration sur l'avenir de la conception durable. Les déchets ne sont plus la fin de l'histoire ; ce n'est que le début.